iSpect DIA-10

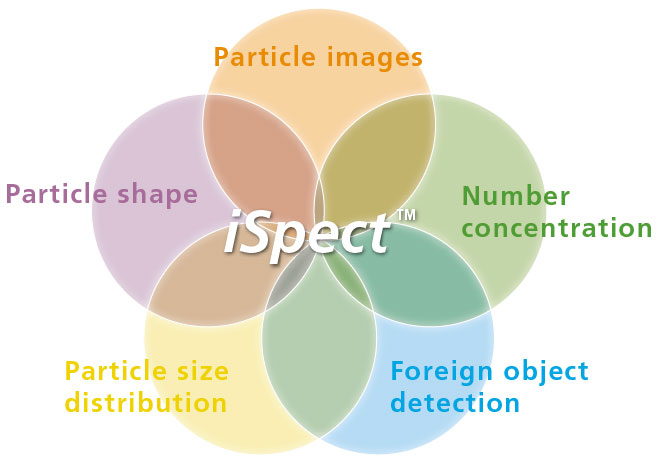

Automatic Measurement of Size, Shape and Number Concentration from Particle Images

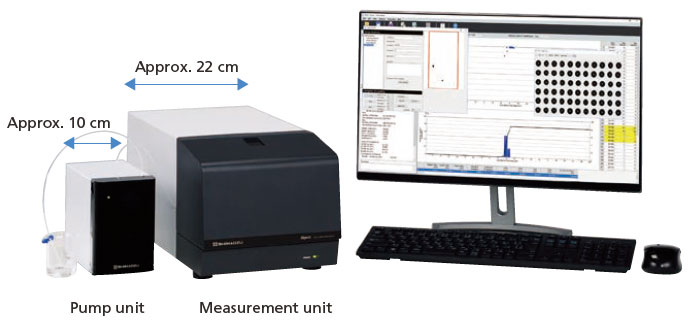

iSpect DIA-10 Dynamic Particle Image Analysis System

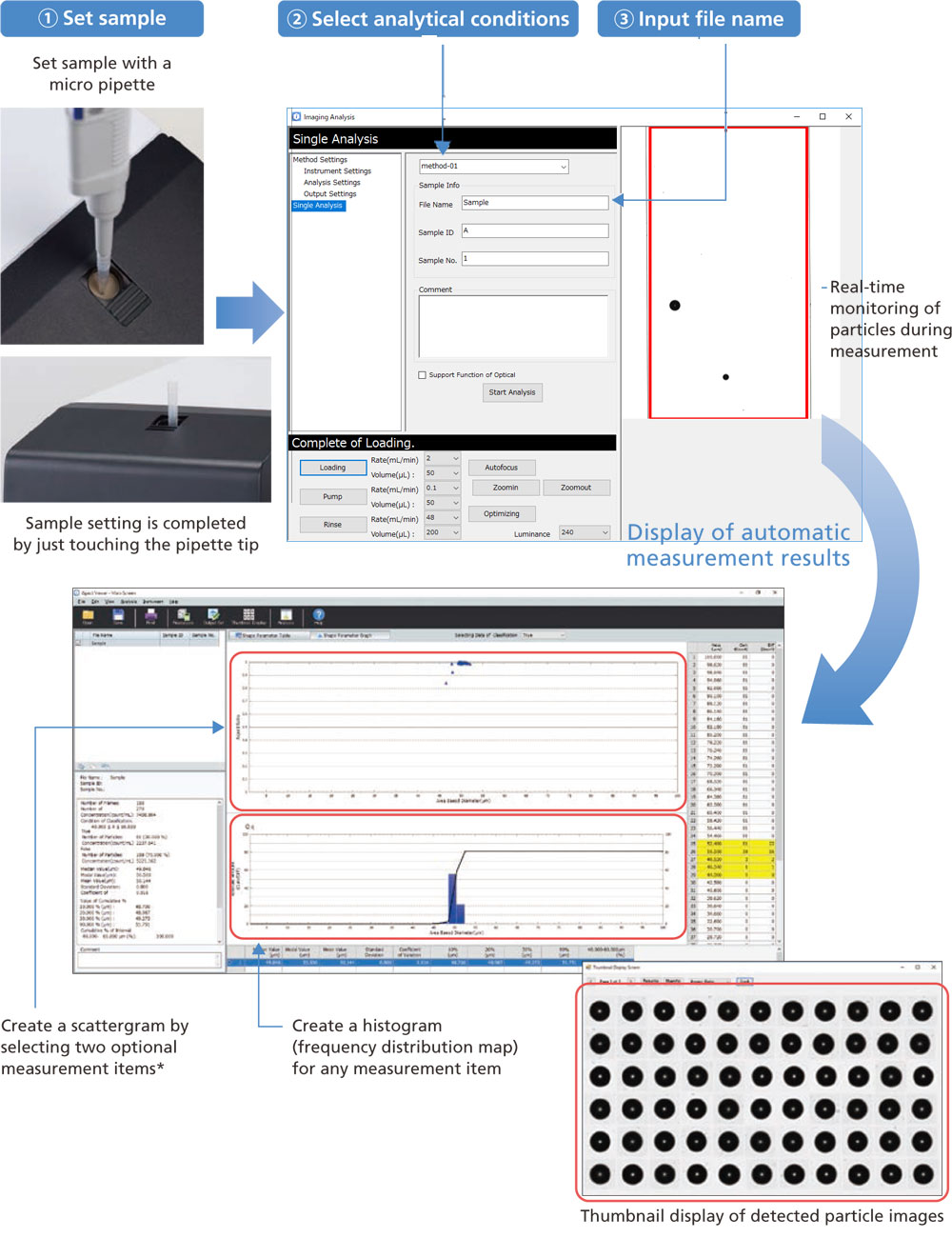

Shimadzu Corporation has released the iSpect DIA-10 system, a dynamic particle image analysis system that automatically measures the size, shape and number concentration of particles by imaging particles in liquid samples. It completes the process in as little as two minutes by imaging particles at high magnification in a liquid sample flowing through the flow path. With this release, Shimadzu has unequivocally entered the market for particle image analysis.

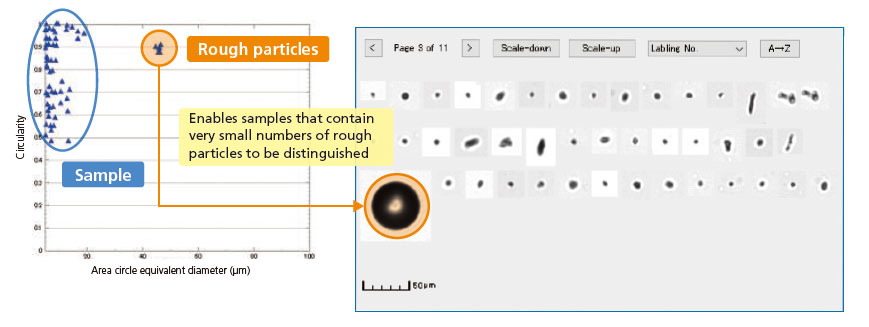

In recent years, with the increasing sophistication of research and development and quality control, there has been a growing need to measure particle shape and detect foreign matter. In light of this demand, Shimadzu has introduced this system, which was developed by leveraging our powder measurement technology and image analysis technology.

As well as conventional applications such as R&D and quality control of paints and pharmaceuticals, the system is also aimed at capturing market share in the particle image analysis industry for new applications such as the R&D of lithium-ion batteries, cellulose nanofibers, and metal powders for 3D printers. Furthermore, we plan to explore the possibility of using this system for research into microplastics, materials that have become a societal problem due to concerns about their adverse effects on the human body and the environment.

Features

1. Enables Measurement of Trace Samples

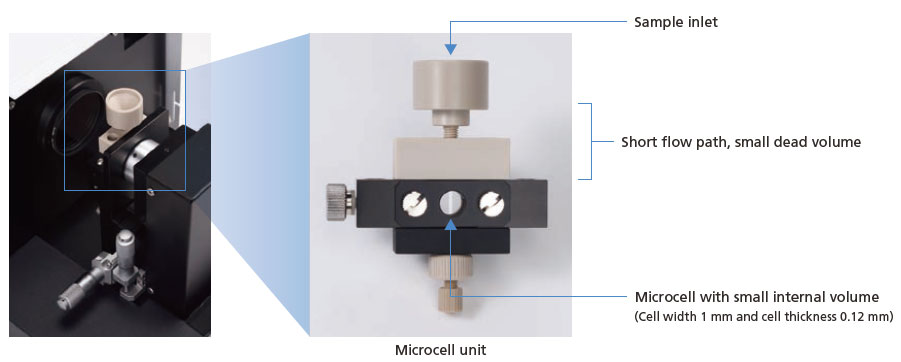

Since it is possible to measure samples as small as 50 μL, the use of rare or expensive samples is minimized, thus reducing measurement costs. Even though organic solvents can be used, the amount needed for cleaning is small, which reduces the amount of waste and minimizes the environmental impact.

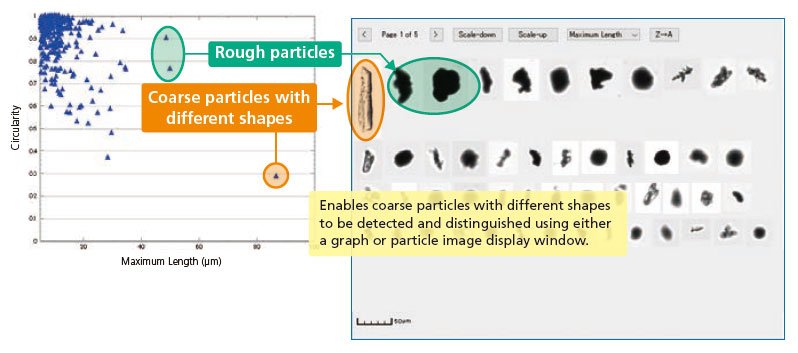

2. Reliable Particle Detection

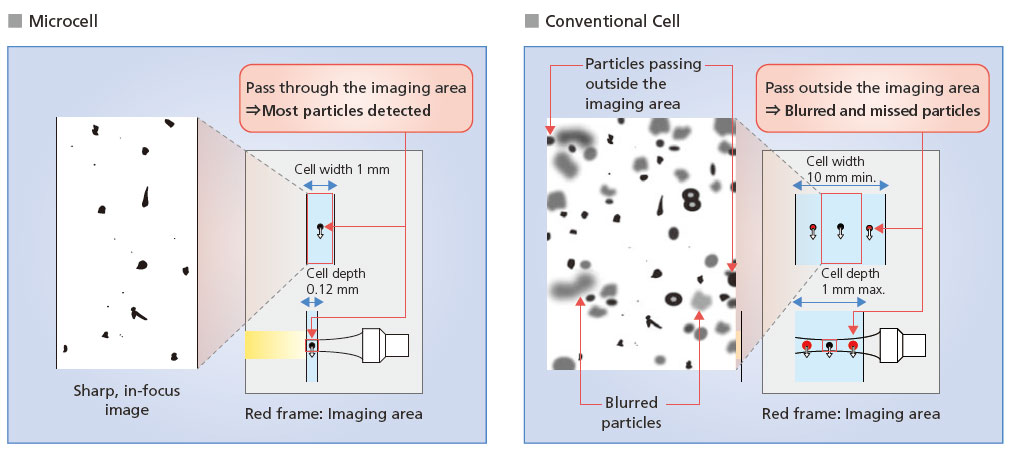

The flow path design minimizes particles passing outside of the camera’s field of view, enabling reliable detection with fewer missed particles. In addition to the high-sensitivity detection of foreign matter and coarse particles contained in the sample, number concentration measurements are highly repeatable.

3. Equipped with Autofocus Function

The system is equipped with an autofocus function that completes camera focusing in about 15 seconds. In addition to shortening the time to perform the operation compared to conventional manual focusing, this also improves productivity by eliminating variation due to manual focusing that affects the data.

All information provided by Shimadzu

https://www.shimadzu.com/an/powder/ispect.html