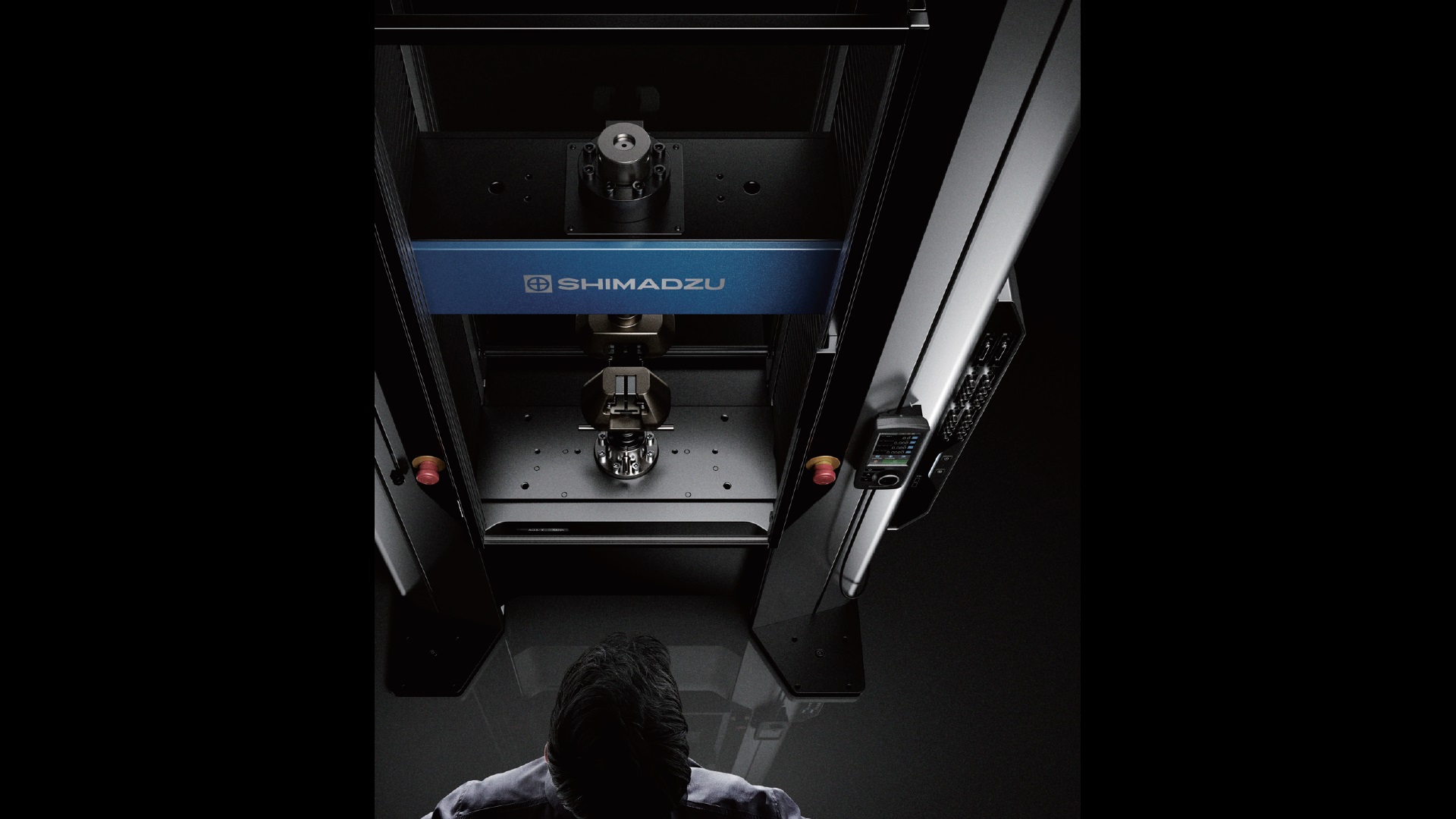

AUTOGRAPH AGX-V Series

This is the AGX-V.

At Shimadzu, our aim is to develop instruments that provide the highest level of test results. To this end, we created the AGX, the highest class of testing machine in the industry. It features a high rigidity frame; multi processors, high-speed sampling and high-accuracy automatic control; an intelligent crosshead; stroke limit switches; a high degree of safety; a smart controller equipped with a progressive user interface; and software that supports the creation of test conditions and data processing with intuitive operability.

Shimadzu has been manufacturing testing machines for more than 100 years. The AGX series is the culmination of the continuous evolution of the AUTOGRAPH based on our wealth of experience and achievements, and insights from customers around the world.

Features

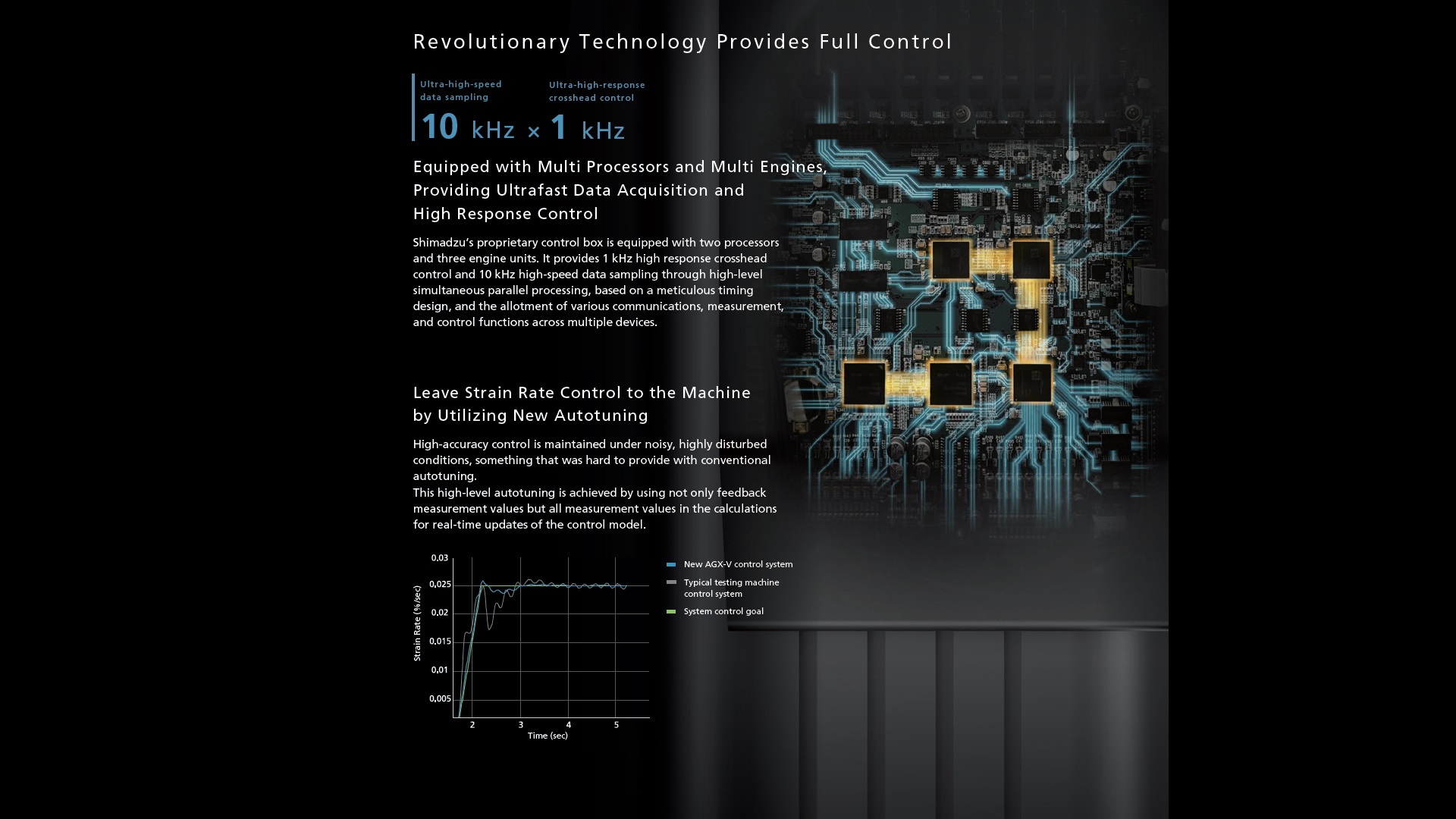

Ensuring High Accuracy Measurements of Strengthened Materials

Higher accuracy testing control is required when testing materials being strengthened for the purpose of reducing the weight of transportation equipment. The combination of AGX-V’s high response real-time autotuning function with the external noise-resistant AEH-3HR automatic extensometer functions effectively in strain rate tests as per the ISO 6892:2016(JIS Z 2241:2011) metallic materials test standards. Additionally, for aging tests in which characteristic values are calculated based on two sets of test results, the functions built into the TRAPEZIUMX-V software reduce the number of calculations performed manually.

AEH-3HR High-Accuracy Automatic Extensometer

This ISO 9513 Class 1 compatible extensometer can measure elongation across a full range of tests, from measuring the modulus of elasticity to the breaking elongation. In combination with the AGX-V series machine, this high-resolution extensometer is compatible with the ISO 6892:2016(JIS Z 2241:2011) strain control requirements.

HFG Hydraulic Flat Grips

(100 kN, 300 kN, 600 kN)

These hydraulic flat grips provide high rigidity and a stable grip force. Opening or closing the grips and changing the grip force can be performed from the smart controller. They are equipped with a sample attachment guide and, in addition, a specially designed hydraulic power source has been adopted, which saves energy through intermittent operation.

MWG Manual Non-Shift Wedge Grips

With these manual grips, turn the handle to grasp the sample. These are popular, cost-effective grips. By replacing the grip teeth, they can accommodate not only flat sheets of material, but also tests of rods.

DT Differential Transformer Extensometer

This extensometer is used for strain measurements of metals, hard plastics, and other samples with comparatively small elongation. In combination with the AGX-V series, it is compatible with electric calibration, which improves user friendliness.

High-Temperature Test Device

This furnace is for high-temperature tests of heat-resistant alloys and ceramics. In combination with a special extensometer, it is compatible with strain measurements and strain control. Select from a lineup featuring a duplex unit that makes the most of the test cycle time, an IR lamp furnace capable of high-speed heating, and a unit with a temperature range up to 1500 °C.

Low-Temperature Test Device

For tests of brittleness, low-temperature immersion tanks for implementing bending tests in liquid nitrogen, and cryostats for creating ultra-low-temperature environments can be created. Tests can be implemented at -196 °C.

* Some of these instruments require special optional parts to connect to a testing machine. Contact your Shimadzu representative.

Improving the Efficiency of Low to Medium Capacity Tests

It is important to control the temperature and humidity conditions when testing materials affected by these conditions. Shimadzu offers a variety atmospheric control testing machines, including refrigerator and gas injection types, to suit the objective. Additionally, the AGX-V’s high-speed return function reduces the standby time during long stroke tests, shortening the test cycle time. Combining switch-operated grips and automatic extensometers further reduces the cycle time.

Device for Atmosphere Tests

Instruments are available for tensile, compression, and bending tests performed in environments not at normal temperatures, including everything from low-temperature to high-temperature environments.

SIE Automatic Extensometer SIE-560A/560SA

This extensometer is equipped with various automatic functions. It automatically detects the grip positions, and moves the elongation measurement arm to a point between the grips. It releases from the sample automatically when the test is finished and returns to the default position, so after attaching the sample, the operator can entrust all the operations to the testing machine, which functions semi-automatically. The lineup also includes a high-accuracy type with a measurement accuracy of ±1 μm.

PFG Pneumatic Flat Grips

With these grips, a foot switch and an interlocked air chuck unit that starts testing automatically after the sample is gripped are selectable. The grips can maintain a stable force even when gripping soft samples that change thickness at the gripped part during testing.

SG Series Strain Gauge Type Extensometer

This is widely used as a manual extensometer. Various types are available depending on the need, including conformity with grades in ISO, JIS, ASTM, and other standards, gauge lengths, and tests under high-temperature conditions.

TRViewX Video Type Non-Contact Extensometer

This is a high-accuracy non-contact extensometer that measures the sample strain from captured images. It can accommodate everything from general materials to films that a contact extensometer cannot be attached to directly.

Bending Deflection Gauge

This deflection gauge for bending tests conforms with ISO 178 and JIS K7171. The displacement gauge is pressed against the lower surface of the sample. The indentation depth on the sample during testing is then measured with high accuracy.

The gauge is equipped with a mechanism that cancels the force used to press the displacement gauge, so it has no effect on the test force measurement.

* Some of these instruments require special optional parts to connect to a testing machine. Contact your Shimadzu representative.

Improving Design, Development, and Analysis Capacities

Validation & Verification (V & V) is required for high-precision simulation, and tests are conducted to load actual products. The auto-tuning function, which maintains the test force with high precision, the analog input function of up to 20 channels, and the WEB camera function are effective for these tests. You can also choose special test jigs to improve the accuracy of the simulation.

Biaxial Tensile Testing

Biaxial tensile tests can be implemented for samples in accordance with ISO 16842. The tensile ratio can be changed by exchanging parts.

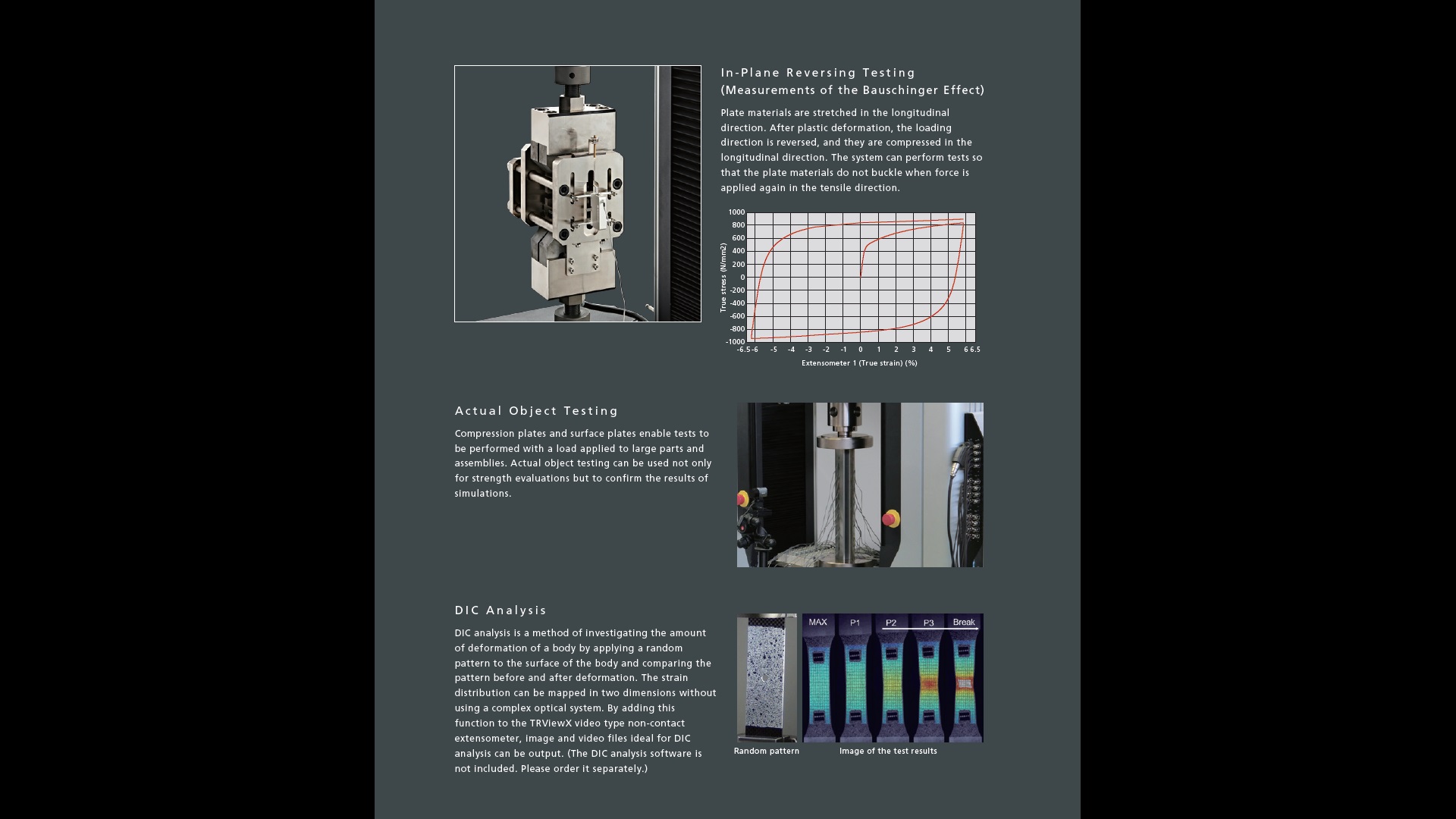

In-Plane Reversing Testing

(Measurements of the Bauschinger Effect)

Plate materials are stretched in the longitudinal direction. After plastic deformation, the loading direction is reversed, and they are compressed in the longitudinal direction. The system can perform tests so that the plate materials do not buckle when force is applied again in the tensile direction.

Actual Object Testing

Compression plates and surface plates enable tests to be performed with a load applied to large parts and assemblies. Actual object testing can be used not only for strength evaluations but to confirm the results of simulations.

DIC Analysis

DIC analysis is a method of investigating the amount of deformation of a body by applying a random pattern to the surface of the body and comparing the pattern before and after deformation. The strain distribution can be mapped in two dimensions without using a complex optical system. By adding this function to the TRViewX video type non-contact extensometer, image and video files ideal for DIC analysis can be output. (The DIC analysis software is not included. Please order it separately.)

* Some of these instruments require special optional parts to connect to a testing machine. Contact your Shimadzu representative.

Applications to New Materials

In the field of new materials development, including composite materials, unique tests are required in order to evaluate the strength of adhesive bonding between different types of materials, and the lowering of strength due to scratches. Our lineup includes items compliant with ISO and JIS as well as ASTM standards, and optional instruments such as a shaft alignment instrument as an entire testing system are also available. Additionally, with ultra-high-speed sampling, a function of the main unit, even abrupt reductions in test force when highly brittle materials break are not overlooked.

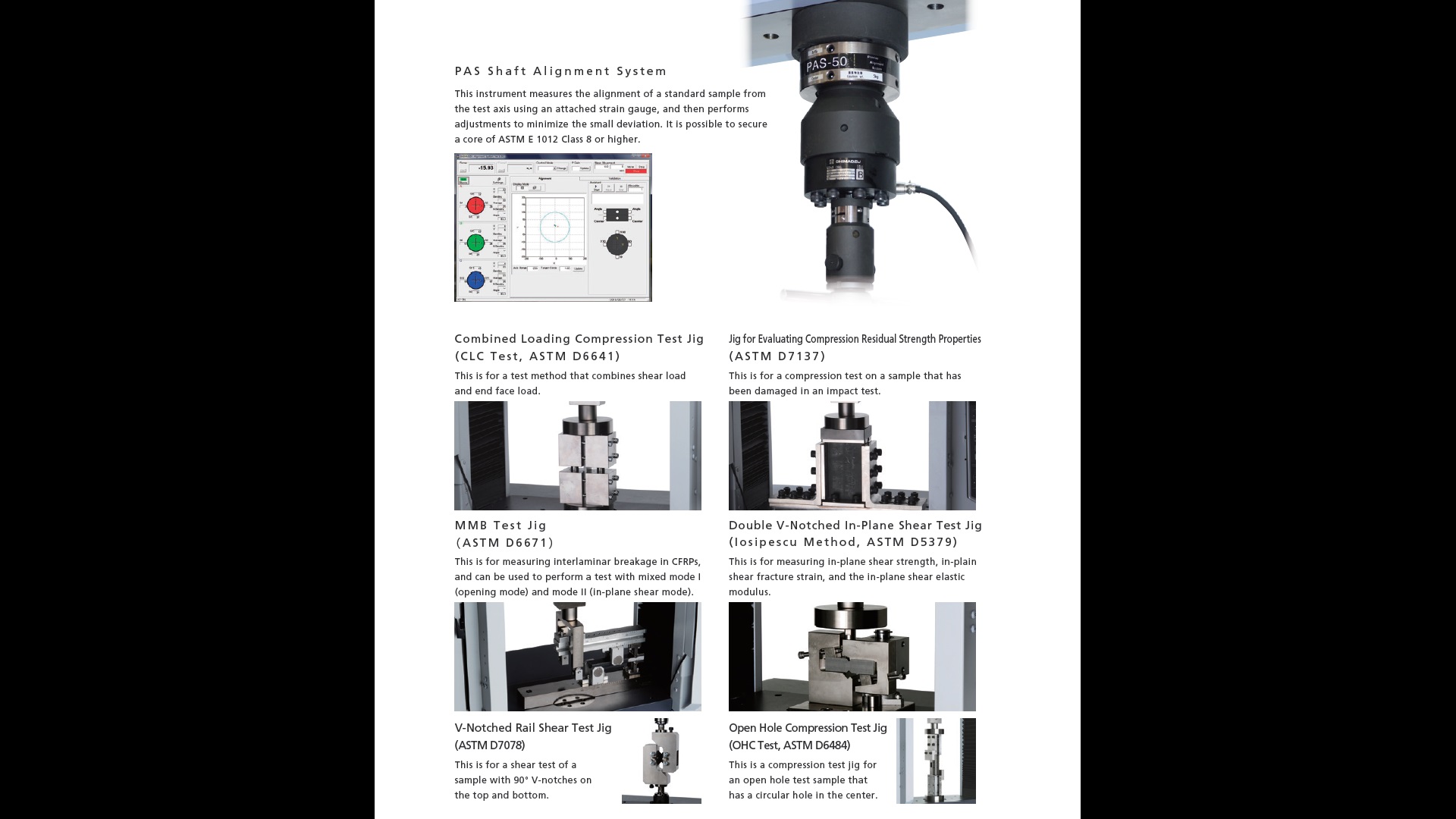

PASS shaft Alignment System

This instrument measures the alignment of a standard sample from the test axis using an attached strain gauge, and then performs adjustments to minimize the small deviation. It is possible to secure a core of ASTM E 1012 Class 8 or higher.

Combined Loading Compression Test Jig

(CLC Test, ASTM D6641)

This is for a test method that combines shear load and end face load.

Jig for Evaluating Compression Residual Strength Properties

(ASTM D7137)

This is for a compression test on a sample that has been damaged in an impact test.

MMB Test Jig

(ASTM D6671)

This is for measuring interlaminar breakage in CFRPs, and can be used to perform a test with mixed mode I (opening mode) and mode II (in-plane shear mode).

Double V-Notched In-Plane Shear Test Jig

(Iosipescu Method,ASTM D5379)

This is for measuring in-plane shear strength, in-plain shear fracture strain, and the in-plane shear elastic modulus.

V-Notched Rail Shear Test Jig

(ASTM D7078)

This is for a shear test of a sample with 90° V-notches on the top and bottom.

Open Hole Compression Test Jig

(OHC Test,ASTM D6484)

This is a compression test jig for an open hole test sample that has a circular hole in the center.

* Some of these instruments require special optional parts to connect to a testing machine. Contact your Shimadzu representative.

The New Software

TRAPEZIUMX-V

Achieves Both Simplicity and High Level Functionality

The software ensures that anyone can easily use the AGX-V, which is equipped with a number of cutting-edge functions. With a flexible UI that accommodates a variety of testing situations, the software is suitable for all users.

Select from Five Software Programs

Single Software

This software is used to perform typical single-direction tests. It enables performing tensile, compression, and bending testing.

Cycle Software

This software enables performing endurance testing and other tests that involve repeated application of test forces.

Control Software

This software enables creating a user-specified testing machine movement routine. It allows tests to be performed in which foam rubber is compressed and held repeatedly.

Texture Software

This software enables measuring the properties (texture) of foodstuffs and pharmaceuticals. Special data processing results, including mastication, jelly strength, and adhesion, can be obtained.

Spring Software

This software enables the testing of springs. Both the characteristic values specific to springs and the spring height and length can be measured.

Visual Wizard Provides Guidance for Setting Parameters with Confidence

Software Wizard for Specifying Parameters for Sample and Data Processing

Software Wizard for Specifying Parameters for Sample and Data Processing- Parameter settings can be specified while viewing the overall sequence using the test parameter wizard.

- Easy-to-understand illustrations are used in windows for specifying parameters for test control, samples, and data processing. Specifying settings is now very easy.

Better, More Flexible Reporting

- Report Designer with Flexible Layout

You can create reports with test results, graphs, photos, logos, and more.

Items on the report can be arranged and sized as desired.

The font, color, and border of each item can also be set finely. - Output reports in PDF, Microsoft Word®, Excel®, and HTML formats

Reports created in the Report Designer can be output in a variety of formats.

Customize reports the way you want with familiar software.

Worry-free Features Ensure Data Reliability

More Reliable Data Management by User Control, Operational Logs, and Automatic Data Transfer Functions

- With the user login function, limits on functionality can be established for each user.

- If the network transmission function is used, the test results can be transferred automatically to a host system when the test is finished. The software is also capable of reorganizing the data in the file to transfer.

- The software has an event log and an operational log function.

- The size of the sample can be read in from electronic calipers, and the sample name can be read in from a bar-code reader.

USB Camera Function Provides Evidence of Testing

- Using a camera with a USB connection, videos interlinked with the start and end of tests can be recorded.

- Samples can be observed with a video playback function interlinked to the stress-strain curve.

- Still images excised from the video can be pasted into reports as test evidence.

Support for Difficult Settings

Easy Conditions Settings Mode Ensures that Anyone Can Start Testing Immediately

The absolute minimum number of settings is gathered together, so tests can be implemented with no confusion. After the test, the test results can be analyzed in detail using the recalculation functions.

Automatic Calculation of the Elastic Modulus with No Parameters Required

The elastic modulus, an important evaluative index for material testing, is calculated automatically with no parameter settings required. Even unknown materials with unknown characteristics can be tested with confidence.

The logic behind the calculations is based on methods recommended in ISO6892-1 (2016) Annex A.

Convenient Features Save Time and Effort

Off-Line Analysis Function Makes Efficient Use of Time Even During Testing

A second instance of the software can be started up off-line during testing. Even in the midst of long tests, the conditions for the next test can be created, and previous results can be analyzed, which saves time.

Quickly Verify Test Control with High-Speed Sensors

Data on strain rates, stress rates and other speeds can be displayed while being calculated in real time. Data that had been determined manually after testing can be calculated automatically, and users can check at a glance that the control accuracy prescribed by regulations is being satisfied.

Web Applications Enable Users to Check Results from Remote Locations

Data on strain rates, stress rates and other speeds can be displayed while being calculated in real time. Data that had been determined manually after testing can be calculated automatically, and users can check at a glance that the control accuracy prescribed by regulations is being satisfied.